Overview

AdmaPrint

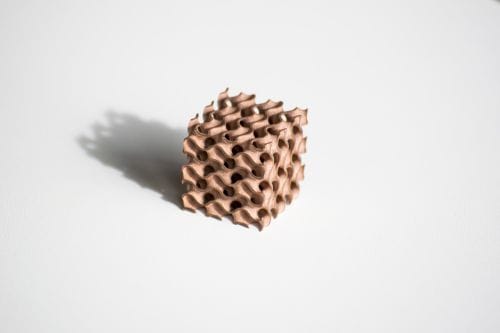

The AdmaPrint feedstock is specially formulated with a mixture of photosensitive resins and a solid load of powder (ceramic or metal), called slurry. The use of light curing and slurries allows achieving high resolutions and very fine surface roughness in printed products. In addition, it prevents health hazards and (cross-)contamination related to the use of dry powders. The AdmaPrint feedstocks can be used to print complex geometries, large and fine structures and a wide variety of functional products.