Overview

Admatec furnaces

Aiming to serve our customers with the full solution needed for 3D printing of advanced ceramic and metal, we provide you with furnaces for the debinding and sintering steps required to obtain fully dense products.

Overview

Aiming to serve our customers with the full solution needed for 3D printing of advanced ceramic and metal, we provide you with furnaces for the debinding and sintering steps required to obtain fully dense products.

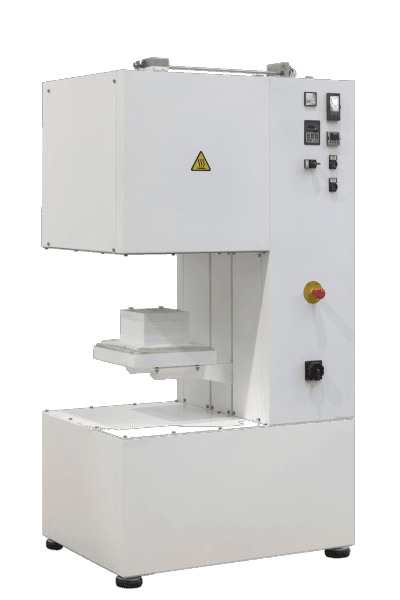

This compact furnace handles both debinding and sintering steps with only one machine, taking up less space in your working environment and saving time. It is ideal for R&D and small series production of ceramic printing applications. The furnace has a chamber that can be moved through a mechanical system, enabling easy loading. With heating elements installed in four lateral walls, there is excellent temperature uniformity.

Specifications of furnace type 450-CH-180

| Maximum operating temperature | 1700°C (oxidizing atmosphere) |

| Dimensions | 180 x 180 x 200 mm |

| Heating elements | 6 pcs Kanthal Super |

| Insulation | Rigid Ceramic Fibre Boards |

| Temperature control | Eurotherm EPC 3008 with 10 different program possibilities |

| Power control | 1 Thyristor Unit, EFIT 25Amp 240V (phase angle operated) |

| Power | 7 + 1 = 8 kW (furnace + preheater) |

| Power supply | 400V 50 Hz (3P+N+PE) or 208V 60 Hz |

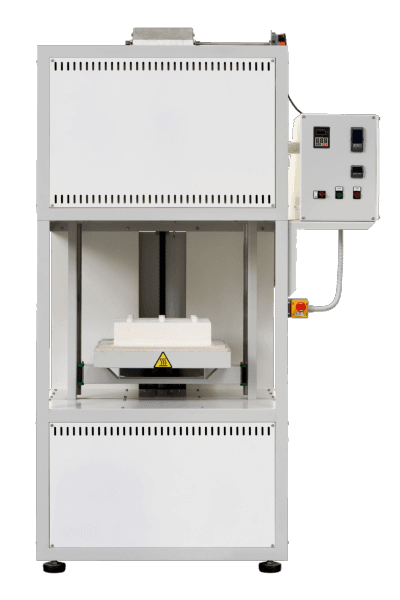

This furnace handles both debinding and sintering steps with only one machine, taking up less space in your working environment and saving time. Due to its large inner volume it is ideal for production of ceramic printing applications. The furnace has a chamber that can be moved through a mechanical system, enabling easy loading. With heating elements installed in four lateral walls, there is excellent temperature uniformity.

Specifications of furnace type 450-CH-400

| Maximum operating temperature | 1700°C (oxidizing atmosphere) |

| Dimensions | 400 x 400 x 400 mm |

| Heating elements | 12 pcs Kanthal Super |

| Insulation | Rigid Ceramic Fibre Boards |

| Temperature control | Eurotherm EPC 3008 with 10 different program possibilities |

| Power control | 3 Thyristor Unit, EFIT 25Amp 240V (phase angle operated) |

| Power | 27 + 3 = 30 kW (furnace + preheater) |

| Power supply | 400V 50 Hz (3P+N+PE) or 208V 60 Hz |

After 3D printing your ceramic parts with the Admaflex 130, they are in the green stage. The debinding furnace will remove the supporting polymers inside your products.

This furnace has the advantage of easy loading and tight sealing. Through an automatic movement system, the loading can easily be facilitated and with heating elements installed in all four lateral walls, excellent temperature uniformity can be reached.

Specifications of furnace type 450-CD-400

| Maximum operating temperature | 1200°C (oxidizing atmosphere) |

| Dimensions | 400 x 400 x 400 mm |

| Heating elements | Kanthal A1 wire |

| Insulation | Rigid Ceramic Fibre Boards |

| Temperature control | Eurotherm EPC3008 with 10 different program possibilities |

| Power control | Solid State Relays for power control |

| Power | 16,5 kW |

| Power supply | 400V 50 Hz (3P+N+PE) |

After firing ceramic products in a debinding furnace, they are in the brown stage. The second and final post-processing step needed is sintering. Through firing the products in a sintering furnace, the atoms in the materials diffuse across the boundaries of the particles, fusing them together and creating one solid piece. This way, a fully dense ceramic end-product will be ensured.

This furnace is equipped with a pneumatic lifting system to simplify loading products in the chamber, while excellent temperature uniformity can be achieved through installed heating elements in all four lateral walls.

Specifications of furnace type 450-CS-400

| Maximum operating temperature | 1750°C (oxidizing atmosphere) |

| Dimensions | 400 x 400 x 400 mm |

| Heating elements | 12 pcs Kanthal Super |

| Insulation | Rigid Ceramic Fibre Boards |

| Temperature control | Eurotherm EPC3008 with 10 different program possibilities |

| Power control | 3 Thyristor Units, EFIT 25Amp 240V (phase angle operated) |

| Power | 26 kW |

| Power supply | 400V 50Hz (3P+N+PE) |

Learn more: