News item

Admatec news

Stay up to date with Admatec news, customer spotlights, and tips on how to leverage 3D printing of ceramics and metals

News

January 29, 2021

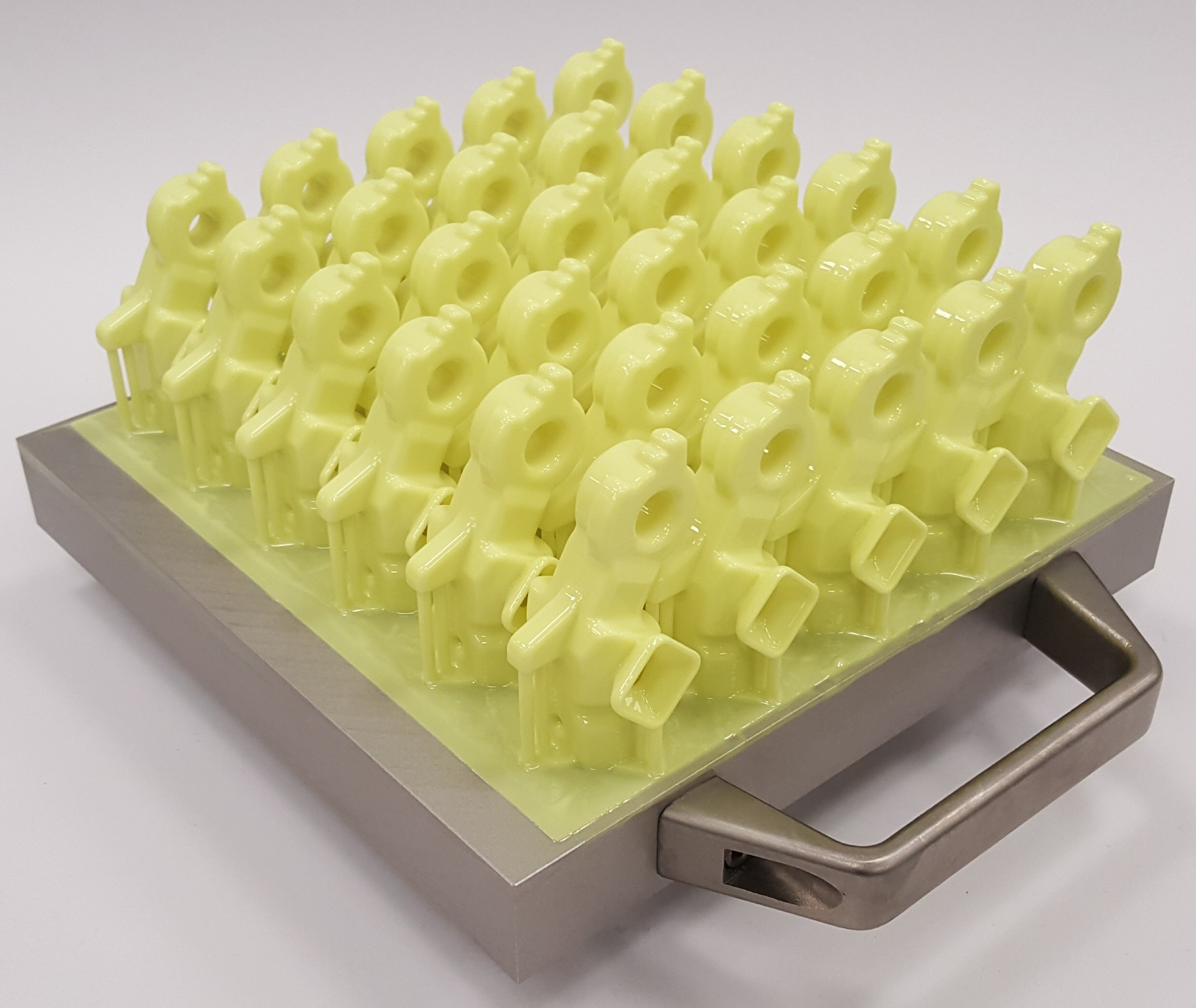

Admaflex Technology allows further increase in productivity and efficiency

The patented Admaflex Technology allows highly efficient 3D printing with help of an improved Stereo Lithograpy based Ceramics Additive Manufacturing process. It is a proven reliable and precise way of 3D printing layer-by-layer, using highly filled photosensitive liquid polymers cured through light. This technology enables the production of high-quality products for high-demanding markets.

When the Admaflex300 was first introduced at Formnext 2019, the system was equipped with a projection area of 200x200 mm. The system allows a build speed of up to 300 layers per hour, which means when printing silica with layers of 200 um, a build speed of 60 mm/hour. The Admaflex300 can be configured according to the customers needs and wishes, with resolutions between 35 um and 88 um. Recently the maximum projection area has been increased with more then 40% to an impressive 260x220 mm.

Are you curious to learn more about the Admaflex Technology and what it can do for you? Please let us know your possible application on the contact form